Recently, GUOZI's intelligent warehouse solution has been put into operation in Chery's "Super Factory" for vehicle production in Qingdao, Shandong. The factory has introduced GUOZI's intelligent logistics AGV system and intelligent WMS system, successfully achieving automation of factory logistics, unmanned operations, and digitized warehousing, thereby breaking through efficiency bottlenecks, reducing manual labor intensity, and lowering operational costs.

Chery Automobile Co., Ltd. is a leading player in the domestic automotive manufacturing industry. Its newly built "Super Factory" in Qingdao spans over 100,000 square meters. The production factory contains thousands of SKUs with significant variations in shape and weight, posing significant challenges in product warehousing management and internal logistics complexity. GUOZI's intelligent warehouse solution, through the integration of intelligent logistics AGV system, intelligent warehouse WMS system, and MES system, enables multi-vehicle dispatching and multidimensional coordination to address user pain points and enhance the overall level of logistics automation in the factory.

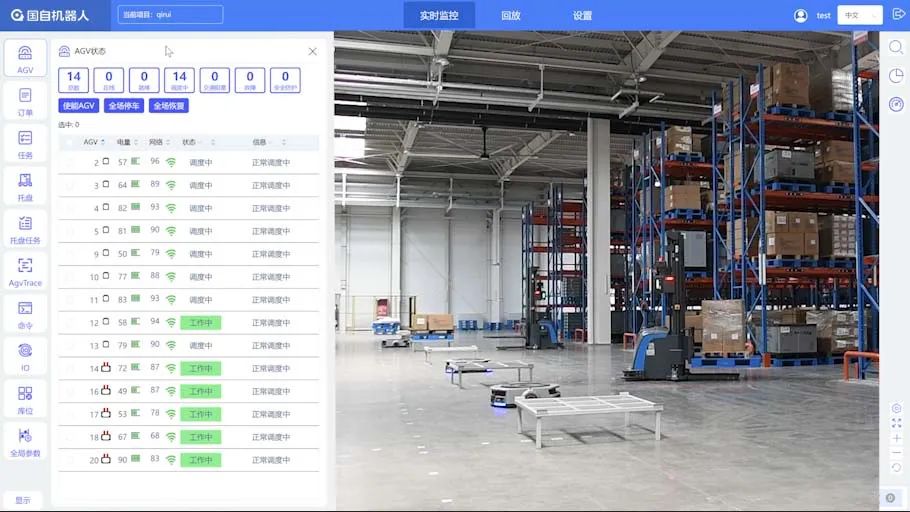

In the high-racking area, qualified components undergo inbound storage tasks executed by forklift stacking AGVs, which transport and store them in the high-racking area. Outbound tasks are collaboratively completed by forklift stacking AGVs and Ants AGVs. In the engine/gearbox sorting area, Ants AGVs handle tasks such as engine and gearbox picking, residual material return, and empty pallet handling. This solution effectively improves warehousing and logistics efficiency as well as automotive production efficiency.

Accurate Docking Multi-Vehicle Coordination for Multiple Vehicle Types and Quantities

Coordinating the operation of two different types of Automated Guided Vehicles (AGVs) requires a high level of precision in docking. In the execution of outbound tasks, the forklift AGV and the Ants AGV work together to transport small and medium-sized materials, achieving warehouse automation and improving production operational efficiency.

Additionally, the system can automatically plan paths for AGVs, enabling intelligent dispatching of multiple vehicles. This comprehensive approach enhances the efficiency of warehousing, logistics, and production operations.

Seamless Information Integration and Intelligent Production Scheduling with Traceability

GUOZI WMS system can seamlessly integrate with the client's existing production management system, enabling traceability of production quality. By utilizing sorting plan algorithm models within the WMS system, it achieves intelligent sorting and redesigns processes such as receiving, storage, outbound, and picking. By collaborating with the MES system, it ultimately achieves optimal material picking, enabling flexible and lean operations for in-plant logistics.

Increasing Storage Capacity with a 6-meter Lift Capability of the Forklift Stacking AGV

The forklift staking AGV is one of the most versatile AGV models in warehousing and logistics scenarios, capable of both handling and stacking functions. In this project, the forklift stacking AGV achieves high-precision docking with 6-meter-high racks in the high-racking area. It fulfills the requirements of loading and unloading materials from multiple levels of racks, greatly enhancing warehouse space utilization. As a result, the warehouse capacity is increased by approximately 70% compared to before.

GUOZI’s intelligent warehouse solution for the automotive industry meets Chery's requirements for automated logistics in their "Super Factory". It enables the separation of personnel and goods within the warehouse, improving operational safety and significantly reducing the number of personnel required for in-warehouse operations. This leads to substantial savings in labor costs and helps customers enhance their industry competitiveness. Furthermore, GUOZI utilizes the GRACE Xpress system for project implementation, which facilitates the smooth launch and operation of the customer's factory, resulting in a significant increase in production capacity.